Prosthetics: A Cybernetic EvolutionCameron Rost Although the term "cyborg" is culturally attached with certain stereotypes or stigmas, many people don't realize that something like prosthetics are incorporated into this term as well. What is a prosthesis? Simply put, a prosthesis is an artificial body part. What is its purpose? The purpose of a prosthesis is to restore independence and mobility to amputees and enable them to do everyday things that most of us take for granted (DVA). Currently, it is estimated that there are between 400,000 to over a million amputees living in the United States, many of them elderly. About 9 out of 10 amputations involve the leg, from the foot to above the knee. Three-fourths of all amputations in the United States result from diseases such as cancer or diabetes. More specifically, many prosthesis users have had peripheral vascular disease, which is often associated with diabetes, and causes narrowing of the arteries in the extremities. Most other amputations are the result of accidents in the workplace or automobile accidents, and a small fraction, perhaps 3 percent, are due to birth defects that constrict bone growth (NY TC). However, the most advances in prosthesis technology have occurred because of wartime amputees, and they are currently the highest-profile recipients of artificial limbs. The ancient Egyptians are considered the early pioneers of prosthetic technology, using splints since 2750 B.C. In fact, archeologists have recently unearthed what is now the oldest known prosthetic in history. In a tomb near the ancient city of Thebes, they found the mummy of a 50 to 60 year old woman with a prosthetic big toe made out of wood, which was held on using leather straps that date back to between 1069 and 664 B.C (Choi). Before this discovery the oldest known prosthetic was the Roman Capua Leg. This leg was discovered at Capua, Italy, in 1858 and dated back to 300 B.C. It was made of bronze and iron, with a wooden core, apparently for a below-knee amputee. The earliest written reference to an artificial limb was around 424 B.C. when the Greek historian Herodotus wrote of a prisoner who was sentenced to death and cut off his own foot to escape, replacing it with a wooden one. A Roman scholar called Pliny the Elder (23-79 A.D.) wrote of a Roman general in the Second Punic War (218-210 B.C.) who had his right arm amputated and had an iron arm fashioned for him so that he could hold his shield and return to battle. In the Dark Ages most prostheses were made for hiding deformities or injuries sustained in battle rather than for daily function. Outside of battle, only the wealthy were lucky enough to be fitted with a peg leg or hand hook for daily function (Norton).

Ambroise Pare is considered to be the father of modern prosthetics; in 1529 he introduced modern amputation procedures to the medical community and started making prostheses in 1536 for upper- and lower- extremity amputees. Around this time a colleague of Pare's named Lorrain used leather, paper, and glue in place of heavy iron to make prosthetics. This contribution made many prosthetics much lighter and easier to handle, making their everyday use more plausible. In 1696, Pieter Verduyn developed the first nonlocking below-knee prosthesis, which would later become the blueprint for current joint and corset devices. Marcel Desoutter made the first aluminum prosthesis with the help of his brother Charles, in 1912 after he lost his leg in an airplane accident (Norton). By the end of the 1800s artificial limbs were created that made movement possible with muscle contractions. After World War II, advancements included better sockets and more lightweight construction. Prosthetics have made many advances throughout history but until recently they have only been on the cusp of potential and possibility. Arm amputees today can choose between prostheses that are powered by a harness and cable attached to the residual limb, or externally powered devices called myoelectric arms that move with a battery powered motor. Switches mounted inside or outside the socket can control powered arms that the patient can activate by flexing certain muscle groups. Prosthetics are usually produced in components so that a professional can design a limb using separate leg, knee, and foot sections combined for optimal fit (NYTC). The newest high-tech prostheses use everything from microprocessors to hydraulics. Computers now design and help manipulate prostheses that transmit nerve impulses and muscle contractions directly to an artificial limb, and experts are hoping a person's brain waves might eventually help power prosthetic devices (Ross). Some prosthetics research is aimed at providing active devices, which do part of the work of the amputated limb, as opposed to passive devices that are controlled by the residual limb. An amputee with prostheses expends two to three times more energy than a nondisabled person to perform even the simplest activities, such as walking across a room or climbing stairs (NYTC). One artificial limb, the C-Leg, uses microprocessors to automatically measure the swing and flexing of the knee 50 times per second and adjust the limb accordingly. To fine-tune the device, a patient can be videotaped as he or she walks wearing the C-Leg while a computer program translates their gait into a stick-figure motion simulation. A computer chip can then be programmed into the limb to create a smooth stride that virtually eliminates a limp. The newest prosthetic knees use microprocessors to mimic motion of the other intact leg at a rate of 1,350 times per second (Ross).

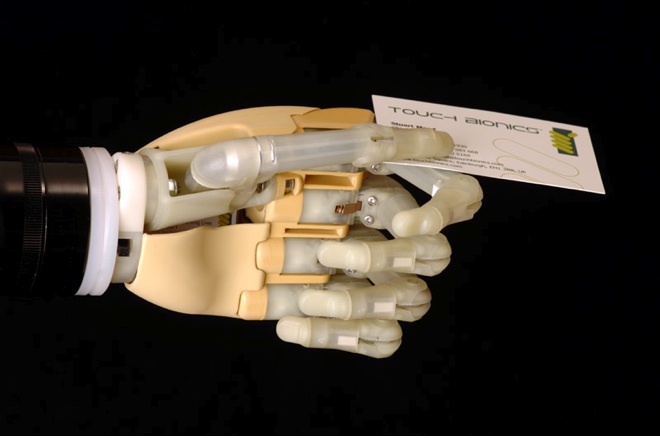

One of the problems that many users of prosthetics had in the past was that they didn't look natural. Nowadays, arms, legs and the joining sections known as sockets are made with advanced lightweight plastics, carbon fiber and silicone-based composites to make the artificial skin more realistic. Since its launch in July 2007, the i-LIMB (not associated with Apple's i-products) has had 700 fittings for hand amputees. The myoelectric arm created by Touch Bionics is the world's first commercially available bionic hand and it is the first advanced prosthetic hand to have each individual finger powered by its own motor, facilitating multiple advanced grip patterns akin to that of a human hand.

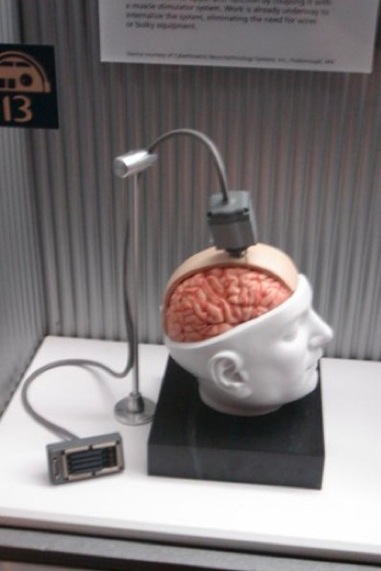

Future improvements are aiming to create individually powered prosthetic fingers, with cables that could transmit nerve impulses from the forearm to the device and allow even more flexible movement (Ross). Interest has also been shown in implantable electrodes for stimulating muscles in spinal cord injuries. Some innovators are also exploring ways to use computers to design and manufacture custom prostheses, to attach muscles directly to prosthesis, to develop powered fingers with microelectronics, and even to use brain waves to power prostheses. One area of research would provide sensory feedback from the prosthesis to the remaining limb. For instance, in an artificial leg, pressure sensors in the foot would send a mild electrical signal to the thigh muscles when there is pressure on the back, front or sides of the foot. Dudley S. Childress of Northwestern University's Rehabilitation Engineering Program is working on applying the industrial practice known as rapid prototyping to socket production. A computer-aided design program is employed to measure the residual limb and design a socket. Then, using a modified plastic deposition technology called squirt shaping, a computer lays down small amounts of polypropylene to produce the desired shape, to very tight tolerances. In industry, the technology is used to quickly produce prototypes of everything from car parts to military weapons in able to test them before starting mass production. The process would also allow manufacturers to make sockets out of different types of material than have been used in the past, or alter the thickness or characteristics of the material very quickly (NYTC). Laboratories are also looking at devices that would improve the “feel” of prostheses over current devices. Cables in artificial limbs would connect to the muscles of the forearm, either through holes in the muscle that are surgically lined with skin, or tendons could be taken outside the residual limb and covered with skin. Either option would give the muscle the sense of how hard it is working and how fast it is moving (Ross). Dr. John Donohue at Brown University has developed a system called Braingate that decodes brain waves-thoughts-and translates them into computer commands. Early results show that a quadriplegic can switch on lights and open email using only his mind. The system, which uses a tiny sensor implanted in the part of the brain that controls movement, has huge implications for amputees: a person could simply “think” about moving his computerized artificial arm, and the thought could trigger the device to act. The system still relies on wires hooked to the brain, but Donohue's group and others pursuing similar work around the country plan to eventually have a wireless system. This research in “neuroprosthetics” is part of a larger trend in prosthetics that aims to integrate body, mind and machine. BIONS, short for bionic neurons, will be injected into residual leg muscles to pick up movement signals from the brain and send them to the artificial limb. BION technology, developed by the Alfred E. Mann Foundation, also figures in an artificial hand invented in the Chicago VA Lab of Dr. Richard Weir. Sensors placed in existing arm muscles will pick up brain signals. An external controller will use “fuzzy logic”, the algebraic decision making of artificial intelligence, to translate the signals into commands for the hand. According to Dr. Danielle Kerkovich of VA's Rehabilitation Research and Development Service, artificial hands of the future will also feature sensory feedback to the brain. In fact, artificial hands of the future will likely contain not only sensors to monitor the force of a grip, but hot and cold sensors as well (DVA).

As technology advances prosthetics will advance as well. Scientists will continue to search for and develop the perfect prosthetic to replace lost limbs. Their goal is not far from completion, which when reached will open the door to the next great prosthetic venture. When the day comes that we can replace lost limbs with perfect replicas we will strive to create even better limbs then the ones we have now. Scientists will create prosthetics that exceed human physical capabilities, and it will be up to the future generation to determine the ethics of upgrades. Images (In chronological order)

1. Digital image. Photo in the News: Mummies' Fake Toes Could Be First Prosthetics. National Geographic Society, 27 July 2007. Web. 3 Mar. 2010. http://news.nationalgeographic.com/news/2007/07/070727-egypt-toe.html

Bibliography

1. Prosthetic Innovations. JP&O Labs. Web. 2 Mar. 2010. http://www.jpo-online.com/innovations.php

|